Lately the weather has been pampering us with summer temperatures. I get out my summer clothes and realise: I need more variety. Boot the PC, visit an online shop, pick out shoes, send order. One day later the doorbell rings. The postman brings me my new trainers – and I shout with joy like in the well-known advertising for an online shop. (*Just kidding*)

How can it be that I place an order in the morning and it’s already delivered the next day? What is happening behind the scenes? And how does it work when goods are returned? The two of us visited UPC’s logistics centre in Bern. We’ll report on this visit and take you along on the logistics journey of UPC parcels.

The trip

We start our trip from Wallisellen on our way to the idyllic Bernese village of Roggwil. When we leave the motorway a few kilometres before reaching Roggwil, we notice that there are some factory and logistics buildings on the way to our intended goal. All this is rounded off by the lush green of a beautiful landscape.

Destination: XPO Logistik – one of our external logistics partners

Arriving at our destination, we see huge logistics buildings. These are older buildings in which previously – and to some extent still – heating pellets and agricultural products are stored. We are greeted by the logistics manager and wait for other colleagues who will also take part in the tour.

Some facts about our logistics

Venhar, our logistics manager for UPC, shows us in a presentation how UPC logistics with the aid of a partner works in detail. We talk about the number of employees, the parts stored, the process of packing and sending, about returns and much more. Here are some facts:

- 15 people work in UPC’s Supply Chain Management Team, among other things supervising and managing the external logistics partners.

- Up to 50 people at XPO Logistik work for UPC.

- About 500 different articles are stored there.

- The articles are spread out in up to 2000 pallet bays in the warehouse.

- About 3 times a week there is a delivery to the UPC shops.

- Once a week delivery to our service partners takes place.

- Each day up to 3000 UPC products leave the XPO warehouse, from Internet Boxes to TV Boxes to Mobile and accessories.

The logistics process

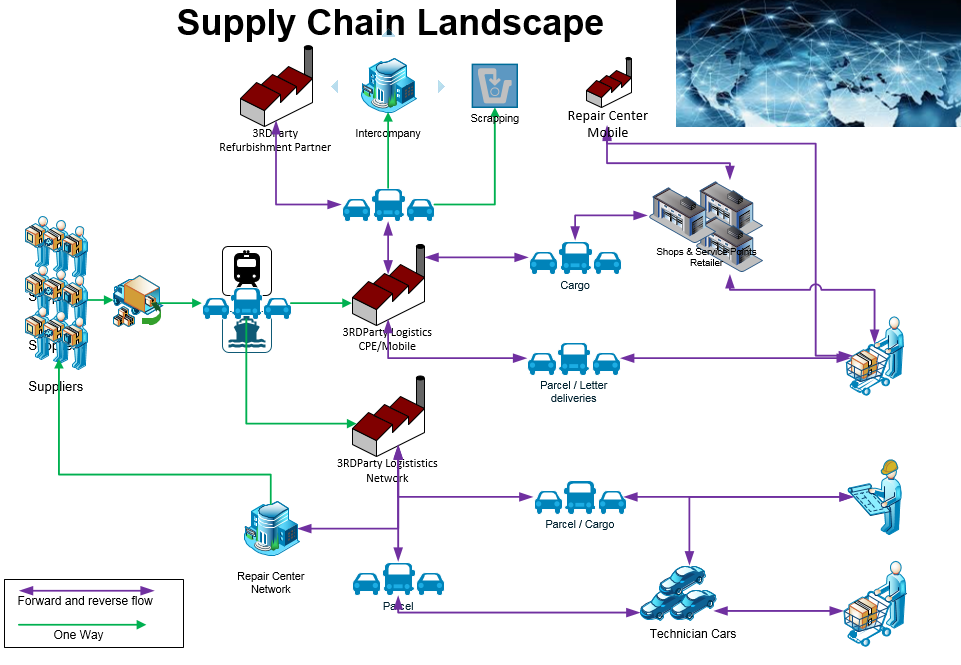

Our logistics partner sends our customer parcels directly to the purchaser. They also supply our shops, service points and partners with materials. In addition there are also the returns from the shops and partners, the service technicians and customers, because of defective or unclaimed parcels. The following chart shows the logistical process:

The order process for our customers (Pick & Pack)

When I’m in the UPC online shop and have placed my order, a few seconds later this appears in our customer data system. In a subsequent process the order is transmitted from the customer data system to the SAP system with which our logistics partner works. Once it has arrived there, the employees put together the goods that were ordered, pack them up, create the delivery note and then send the parcel. All our customer devices are delivered to the warehouse as mass commodities, or as raw materials. There they are unpacked and equipped with accessories such as remote control, HDMI cable, LAN cable, Quick Installation Guide and a power supply unit. The set is carefully enhanced with UPC brand packaging. Our logistics partner calls this procedure “assembly”. Then the parcel moves along a conveyor and is shrink-wrapped in protective film.

Delivery to the shops, service points and partners

Our shops, partners and service points reorder what they need on their own. They initiate the orders through the process they know at UPC. In contrast to direct delivery to our customers, we supply them with fully loaded transport trolleys. Smartphones are packed into a crate with a tamper-proof seal. In this way we ensure than nothing disappears along the transport route. We use a grey seal for delivery to our service points and a purple one for returns to our logistics partners.

Returned goods – what happens to them?

When my clothing no longer fits, I dispose of it by bringing it to the clothing drive. Our customers send old devices back to us or hand them over in our shops and service centres. Old devices can actually also be disposed of by bringing them to any electrical retailer nearby. When new goods are delivered, the returns are taken along right away – per day that’s up to 15 full post trolleys. Once arrived in our logistics centre, they get unpacked. Older devices which we no longer offer, our partners dispose of properly for us. All other devices are inspected by an employee and according to the guidelines they are either released for disposal or forwarded to our repair partner. The latter “refurbishes” the device, replaces the defective parts, updates it and sends it back to UPC. Now there is no reason not to use this “new recycled device” again.

Here are some impressions of our returns:

The end of the tour

After the tour I’m still marvelling at the vast warehouse. All articles are stacked high and get stacked or unloaded by the pile hoist. Venhar mentions another little area which is very important: “Critical spare parts”. In this storage area we keep important network components which must be replaced in the event of a power failure. The area is accessible to a delivery service 24 hours a day, 7 days a week. If a network component is needed, the delivery service is asked to take this from the warehouse and deliver it directly to the affected location. Here speed is of the essence, since our customers are without available services and we want to make these accessible again as quickly as possible. In conclusion we ask Venhar whether our customers also return things that have nothing to do with UPC. He laughs and shows us a SALT router which was returned to us. One of many examples.

We thank Venhar and his team for this great morning and say goodbye to them. During our 60-minute return trip we talk about what we have just experienced. Just imaging the logistic challenge of an Amazon shop – unbelievable how huge the warehouse would have to be so that all articles are stored ideally and can be made ready for shipping.

(Behind the Scenes - Day 5 - Visiting the logistics centre)